- Mobile: 0086-18616206301

- Skype:zhou-junliang

- E-mail: jason@chenghuibearing.com

-

cam-followers-total-catalog.pdf

cam-followers-total-catalog.pdf

-

metric-cam-followers-total-catalog.pdf

metric-cam-followers-total-catalog.pdf

-

inch-cam-followers-total-catalog.pdf

inch-cam-followers-total-catalog.pdf

-

miniaute-cam-followers-total-catalog.pdf

miniaute-cam-followers-total-catalog.pdf

-

cam-followers-accuracy-and-fit.pdf

cam-followers-accuracy-and-fit.pdf

-

Accessoriesforcamfollowers.pdf

Accessoriesforcamfollowers.pdf

Cam followers have an internal design very similar to that of a needle or cylindrical roller bearing. They are characterized by a thick-walled outer ring that enables them to accommodate shock loads while reducing distortion and bending stresses. The outer ring running surface is crowned as standard. However,cam followers with cylindrical (flat) running surfaces are available for certain applications.

Instead of an inner ring, cam followers have a solid stud (pin) that is threaded so that the cam follower can be quickly and easily attached to appropriate machine components by means of a hexagonal nut. Axial guidance for the outer ring is provided by an integral flange at the head of the stud and a flange ring pressed onto the stud, or by the roller complement. Cam followers are pregreased, ready-to-mount units that are suitable for all types of cam drives, tracks and conveyor systems.

Among them KR, NUKR and PWKR Sseries have the same main dimensions. The differences are in their internal design, which make them suitable for various operating conditions.

All designs are available with a concentric seat or an eccentric collar on the stud. An eccentric collar, which has a shrink-fit onto the stud, enables less stringent manufacturing tolerances to be specified for associated components. The values for the adjustable eccentricity are listed in the product tables.

C&H suppliers both standard metric and inch stud type cam follower bearigns and custom capabilities

Customer specified factory grease fill

Grease fitting installed

Stud or thread length modifications

Roller diameter variations or tolerances

Cam followers grouped or matched diameter tolerance / run out sets

Cam followering materials and surface treatments

Customer engineered to order designs

Why choose C&H cam followings ?

C&H focus on supply high quality cam followings. Reliable and high-quality products reduce the loss of downtime, which can help users save money.

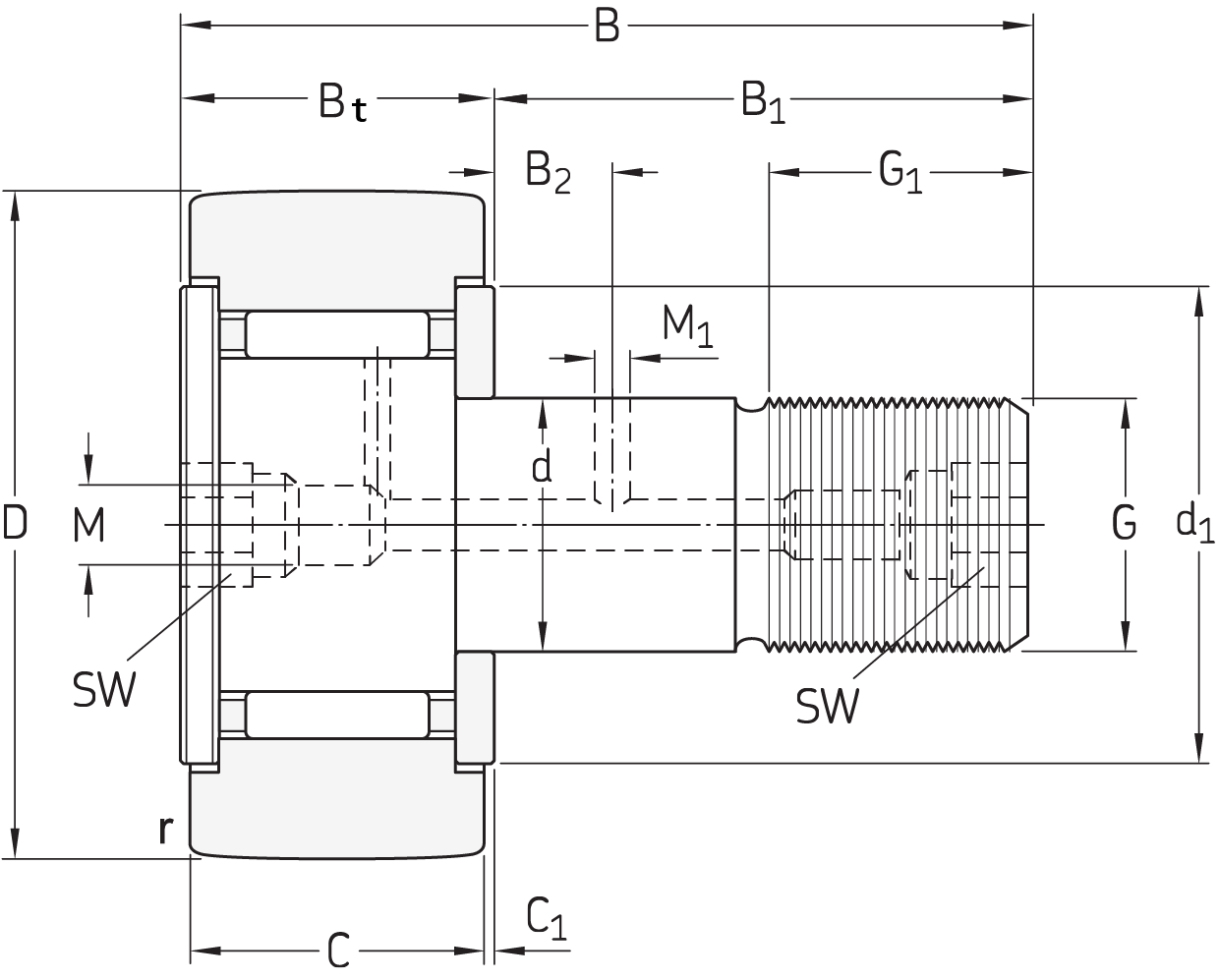

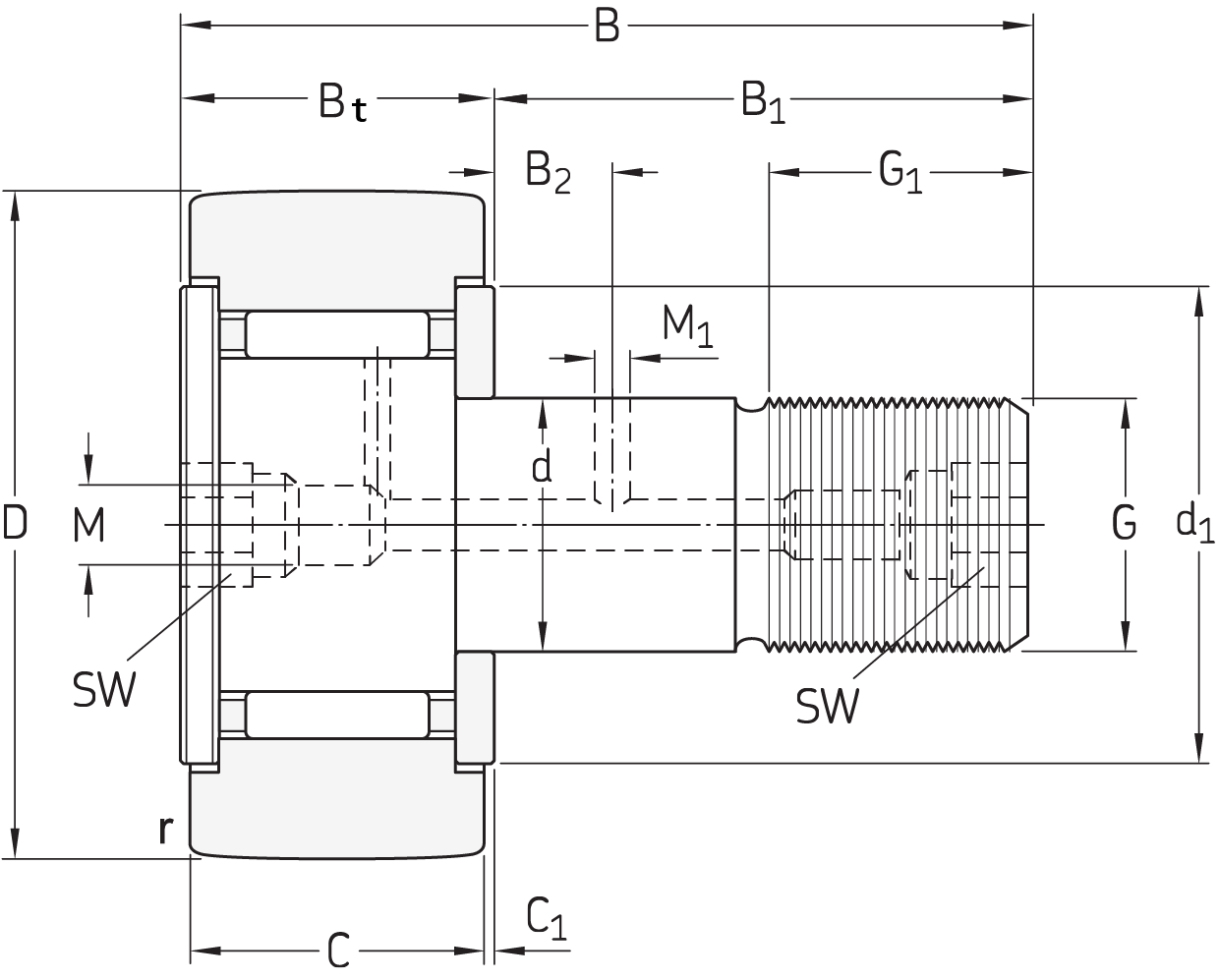

| Designation | Dimensions (mm) | Mass | |||||||||||||

| D | C | d | B | B1 | B2 | C1 | d1 | G | G1 | M | M1 | r | SW | kg | |

| KR13 | 13 | 9 | 5 | 23 | 13 | 0.6 | 9 | M5x0.8 | 7.5 | 0.3 | 0.02 | ||||

| KR16 | 16 | 11 | 6 | 28 | 16 | 0.6 | 12.5 | M6x1 | 8 | 4 | 0.15 | 0.02 | |||

| KR19 | 19 | 11 | 8 | 32 | 20 | 0.6 | 15 | M8x1.25 | 10 | 4 | 0.15 | 0.032 | |||

| KR22 | 22 | 12 | 10 | 36 | 23 | 0.6 | 17.5 | M10x1 | 12 | 0.3 | 5 | 0.045 | |||

| KR26 | 26 | 12 | 10 | 36 | 23 | 0.6 | 17.5 | M10x1 | 12 | 0.3 | 5 | 0.061 | |||

| KR30 | 30 | 14 | 12 | 40 | 25 | 6 | 0.6 | 23 | M12x1.5 | 13 | 3 | 0.3 | 6 | 0.09 | |

| KR32 | 32 | 14 | 12 | 40 | 25 | 6 | 0.6 | 23 | M12x1.5 | 13 | 3 | 0.3 | 6 | 0.1 | |

| KR35 | 35 | 18 | 16 | 52 | 32.5 | 8 | 0.8 | 27.6 | M16x1.5 | 17 | 3 | 0.3 | 8 | 0.17 | |

| KR40 | 40 | 20 | 18 | 58 | 36.5 | 8 | 0.8 | 31.5 | M18x1.5 | 19 | 3 | 1 | 8 | 0.25 | |

| KR47 | 47 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 36.5 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.39 |

| KR52 | 52 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 36.5 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.47 |

| KR62 | 62 | 29 | 24 | 80 | 49.5 | 11 | 0.8 | 44 | M24x1.5 | 25 | 8 | 4 | 1 | 14 | 0.8 |

| KR72 | 72 | 29 | 24 | 80 | 49.5 | 11 | 0.8 | 44 | M24x1.5 | 25 | 8 | 4 | 1.1 | 14 | 1.05 |

| KR80 | 80 | 35 | 30 | 100 | 63 | 15 | 1 | 53 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.56 |

| KR85 | 85 | 35 | 30 | 100 | 63 | 15 | 1 | 53 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.74 |

| KR90 | 90 | 35 | 30 | 100 | 63 | 15 | 1 | 53 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.97 |

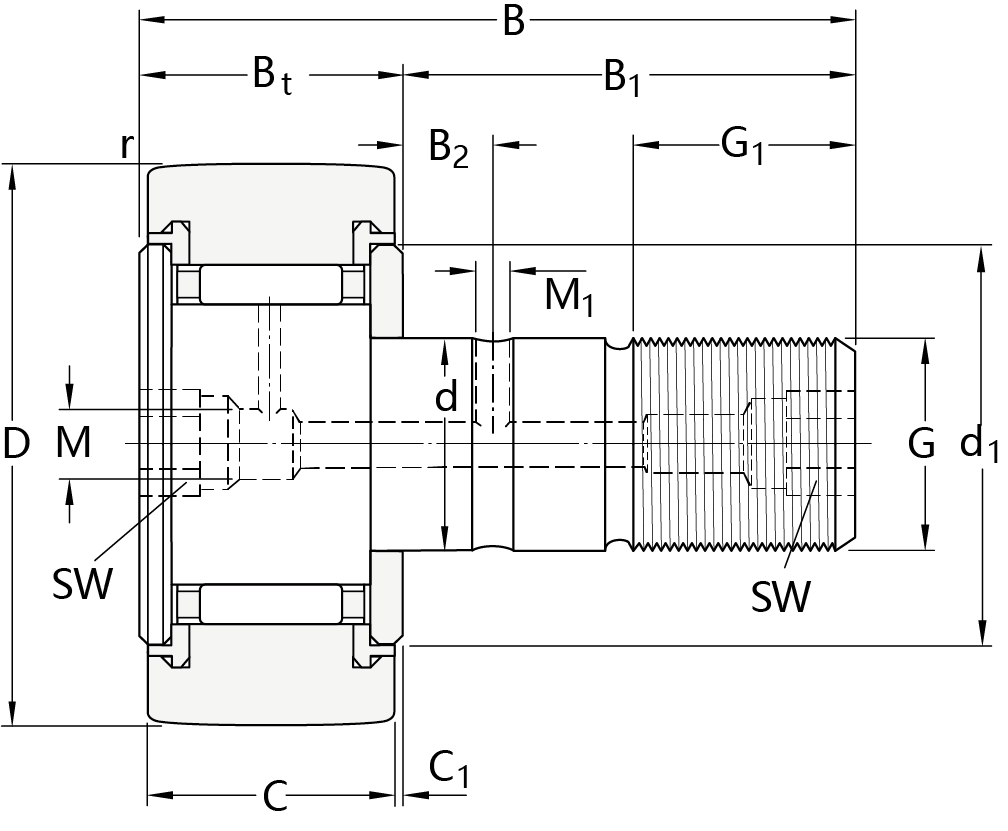

| Designation | Dimensions (mm) | Mass | |||||||||||||

| D | C | d | B | B1 | B2 | C1 | d1 | G | G1 | M | M1 | r | SW | kg | |

| KR13PP | 13 | 9 | 5 | 23 | 13 | 0.6 | 9 | M5x0.8 | 7.5 | 0.3 | 0.02 | ||||

| KR16PP | 16 | 11 | 6 | 28 | 16 | 0.6 | 12.5 | M6x1 | 8 | 4 | 0.15 | 0.02 | |||

| KR19PP | 19 | 11 | 8 | 32 | 20 | 0.6 | 15 | M8x1.25 | 10 | 4 | 0.15 | 0.032 | |||

| KR22PP | 22 | 12 | 10 | 36 | 23 | 0.6 | 17.5 | M10x1 | 12 | 0.3 | 5 | 0.045 | |||

| KR26PP | 26 | 12 | 10 | 36 | 23 | 0.6 | 17.5 | M10x1 | 12 | 0.3 | 5 | 0.061 | |||

| KR30PP | 30 | 14 | 12 | 40 | 25 | 6 | 0.6 | 23 | M12x1.5 | 13 | 3 | 0.3 | 6 | 0.09 | |

| KR32PP | 32 | 14 | 12 | 40 | 25 | 6 | 0.6 | 23 | M12x1.5 | 13 | 3 | 0.3 | 6 | 0.1 | |

| KR35PP | 35 | 18 | 16 | 52 | 32.5 | 8 | 0.8 | 27.6 | M16x1.5 | 17 | 3 | 0.3 | 8 | 0.17 | |

| KR40PP | 40 | 20 | 18 | 58 | 36.5 | 8 | 0.8 | 31.5 | M18x1.5 | 19 | 3 | 1 | 8 | 0.25 | |

| KR47PP | 47 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 36.5 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.39 |

| KR52PP | 52 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 36.5 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.47 |

| KR62PP | 62 | 29 | 24 | 80 | 49.5 | 11 | 0.8 | 44 | M24x1.5 | 25 | 8 | 4 | 1 | 14 | 0.8 |

| KR72PP | 72 | 29 | 24 | 80 | 49.5 | 11 | 0.8 | 44 | M24x1.5 | 25 | 8 | 4 | 1.1 | 14 | 1.05 |

| KR80PP | 80 | 35 | 30 | 100 | 63 | 15 | 1 | 53 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.56 |

| KR85PP | 85 | 35 | 30 | 100 | 63 | 15 | 1 | 53 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.74 |

| KR90PP | 90 | 35 | 30 | 100 | 63 | 15 | 1 | 53 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.97 |

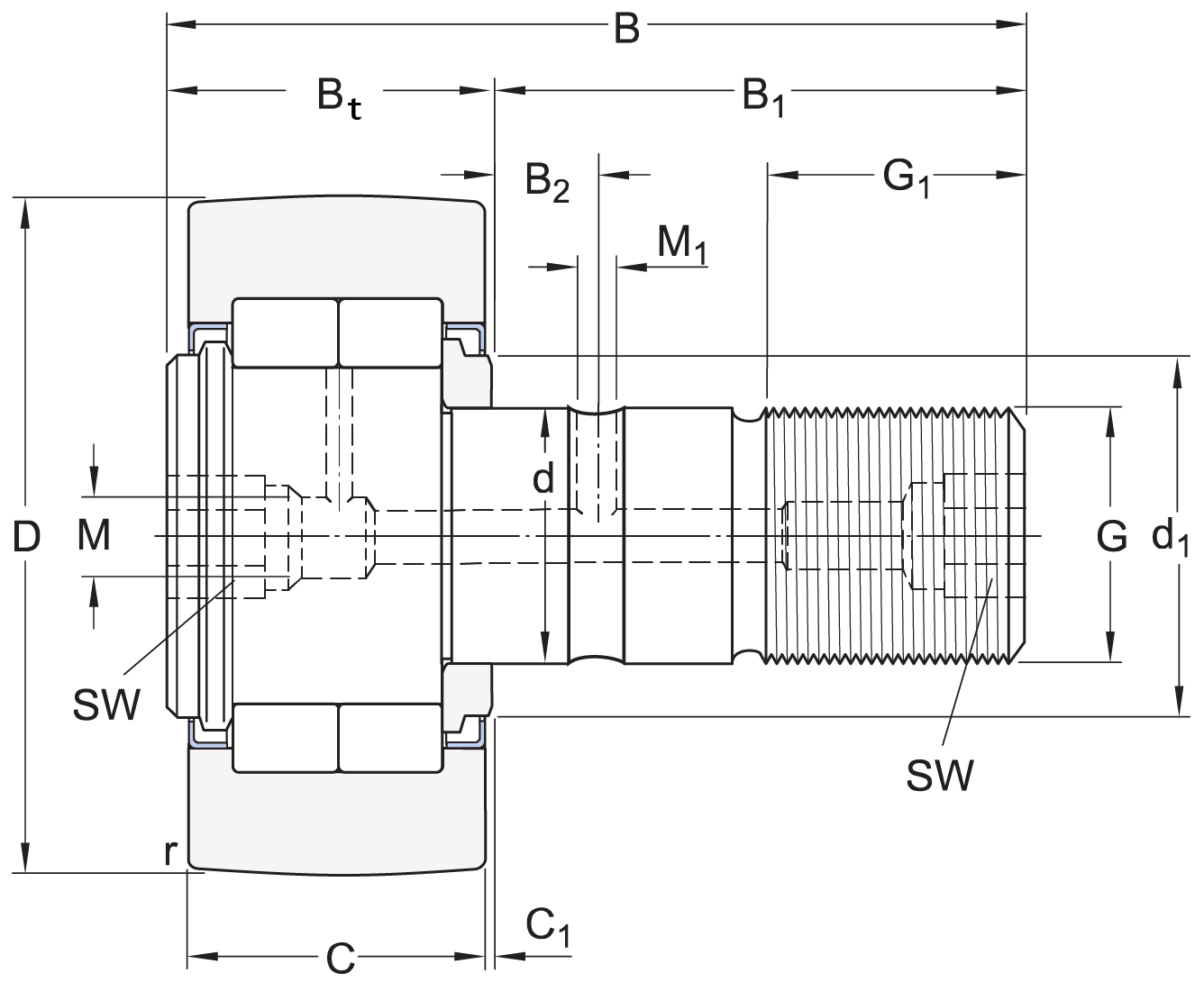

| Designation | Dimensions (mm) | Mass | |||||||||||||

| D | C | d | B | B1 | B2 | C1 | d1 | G | G1 | M | M1 | r | SW | kg | |

| NUKR35 | 35 | 18 | 16 | 52 | 32.5 | 8 | 3.8 | 20 | M16x1.5 | 17 | 6 | 3 | 0.3 | 8 | 0.16 |

| NUKR40 | 40 | 20 | 18 | 58 | 36.5 | 8 | 3.8 | 22 | M18x1.5 | 19 | 6 | 3 | 1 | 8 | 0.24 |

| NUKR47 | 47 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 27 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.38 |

| NUKR52 | 52 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 31 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.45 |

| NUKR62 | 62 | 29 | 24 | 80 | 49.5 | 11 | 1.3 | 38 | M24x1.5 | 25 | 8 | 4 | 1 | 14 | 0.80 |

| NUKR72 | 72 | 29 | 24 | 80 | 49.5 | 11 | 1.3 | 44 | M24x1.5 | 25 | 8 | 4 | 1.1 | 14 | 1.02 |

| NUKR80 | 80 | 35 | 30 | 100 | 63 | 15 | 1 | 47 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.60 |

| NUKR85 | 85 | 35 | 30 | 100 | 63 | 15 | 1 | 47 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.74 |

| NUKR90 | 90 | 35 | 30 | 100 | 63 | 15 | 1 | 47 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.96 |

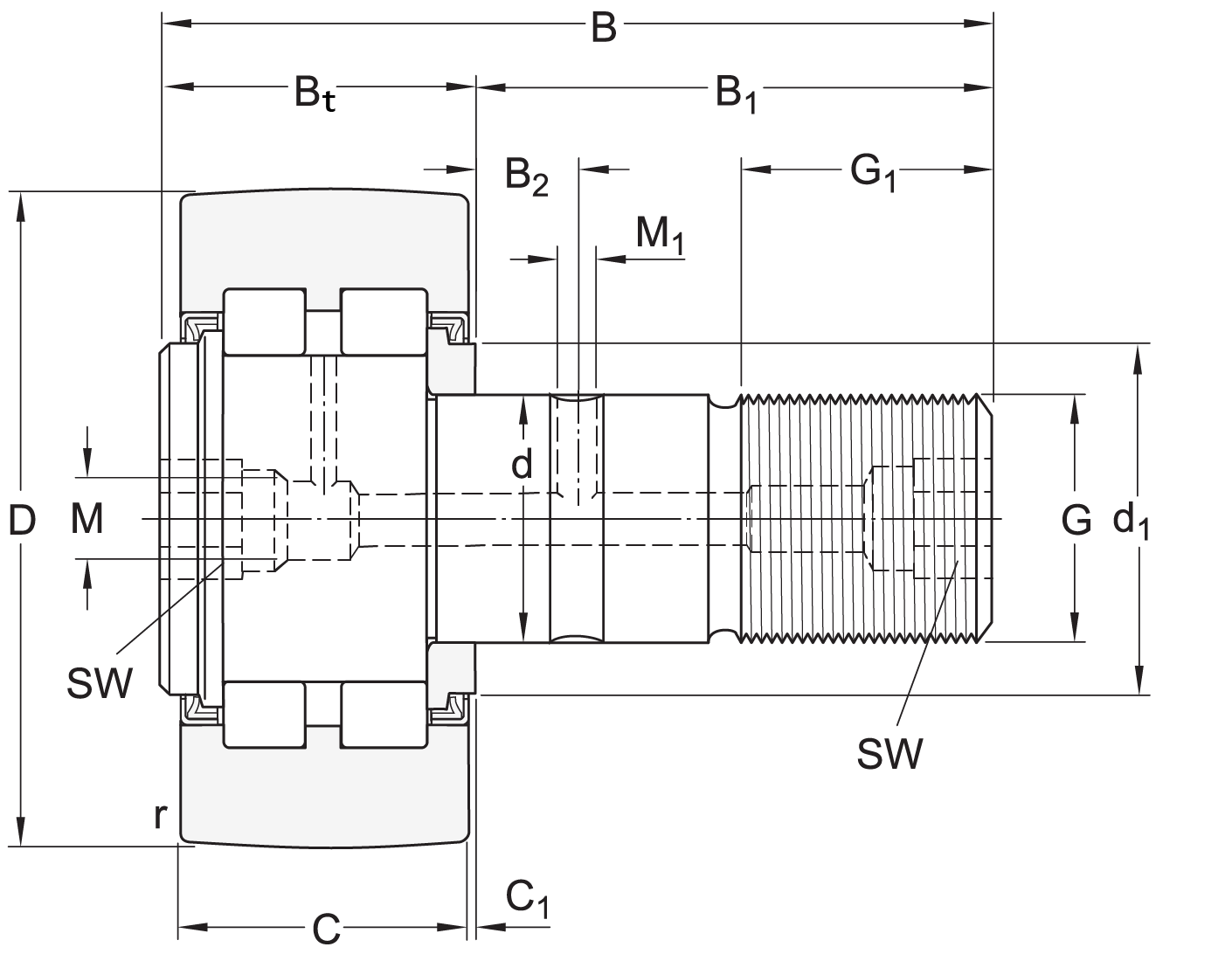

| Designation | Dimensions (mm) | Mass | |||||||||||||

| D | C | d | B | B1 | B2 | C1 | d1 | G | G1 | M | M1 | r | SW | kg | |

| PWKR35-2RS | 35 | 18 | 16 | 52 | 32.5 | 8 | 3.8 | 20 | M16x1.5 | 17 | 6 | 3 | 0.3 | 8 | 0.16 |

| PWKR40-2RS | 40 | 20 | 18 | 58 | 36.5 | 8 | 3.8 | 22 | M18x1.5 | 19 | 6 | 3 | 1 | 8 | 0.24 |

| PWKR47-2RS | 47 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 27 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.38 |

| PWKR52-2RS | 52 | 24 | 20 | 66 | 40.5 | 9 | 0.8 | 31 | M20x1.5 | 21 | 8 | 4 | 1 | 10 | 0.45 |

| PWKR62-2RS | 62 | 29 | 24 | 80 | 49.5 | 11 | 1.3 | 38 | M24x1.5 | 25 | 8 | 4 | 1 | 14 | 0.80 |

| PWKR72-2RS | 72 | 29 | 24 | 80 | 49.5 | 11 | 1.3 | 44 | M24x1.5 | 25 | 8 | 4 | 1.1 | 14 | 1.02 |

| PWKR80-2RS | 80 | 35 | 30 | 100 | 63 | 15 | 1 | 47 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.60 |

| PWKR85-2RS | 85 | 35 | 30 | 100 | 63 | 15 | 1 | 47 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.74 |

| PWKR90-2RS | 90 | 35 | 30 | 100 | 63 | 15 | 1 | 47 | M30x1.5 | 32 | 8 | 4 | 1.1 | 14 | 1.96 |

| Designation | Dimensions (inch) | |||||||

|

|

D | C | B | B1 | G1 | G | SW | lbs |

| CF-1/2-SB | 0.5 | 0.375 | 1.0312 | 0.625 | 0.25 | 10-32 | 0.125 | 0.037 |

| CF- 5/8 -SB | 0.625 | 0.4375 | 1.2187 | 0.75 | 0.3125 | 1/4-28 | 0.125 | 0.062 |

| CF- 3/4 -SB | 0.75 | 0.5 | 1.4062 | 0.875 | 0.375 | 3/8-24 | 0.1875 | 0.11 |

| CF- 7/8 -SB | 0.875 | 0.5 | 1.4062 | 0.875 | 0.375 | 3/8-24 | 0.1875 | 0.137 |

| CF-1-SB | 1 | 0.625 | 1.6562 | 1 | 0.5 | 7/16 -20 | 0.25 | 0.205 |

| CF-1 1/8 -SB | 1.125 | 0.625 | 1.6562 | 1 | 0.5 | 7/16 -20 | 0.25 | 0.249 |

| CF-1 1/4 -SB | 1.25 | 0.75 | 2.0312 | 1.25 | 0.625 | 1/2-20 | 0.25 | 0.357 |

| CF-1 3/8 -SB | 1.375 | 0.75 | 2.0312 | 1.25 | 0.625 | 1/2-20 | 0.25 | 0.419 |

| CF-1 1/2 -SB | 1.5 | 0.875 | 2.4062 | 1.5 | 0.75 | 5/8-18 | 0.3125 | 0.617 |

| CF-1 5/8 -SB | 1.625 | 0.875 | 2.4062 | 1.5 | 0.75 | 5/8-18 | 0.3125 | 0.703 |

| CF-1 3/4 -SB | 1.75 | 1 | 2.7812 | 1.75 | 0.875 | 3/4-16 | 0.3125 | 0.97 |

| CF-1 7/8 -SB | 1.875 | 1 | 2.7812 | 1.75 | 0.875 | 3/4-16 | 0.3125 | 1.086 |

| CF-2-SB | 2 | 1.25 | 3.2812 | 2 | 1 | 7/8-14 | 0.4375 | 1.587 |

| CF-2 1/4 -SB | 2.25 | 1.25 | 3.2812 | 2 | 1 | 7/8-14 | 0.4375 | 1.858 |

| CF-2 1/2 -SB | 2.5 | 1.5 | 3.7812 | 2.25 | 1.125 | 1-14 | 0.5 | 2.727 |

| CF-2 3/4 -SB | 2.75 | 1.5 | 3.7812 | 2.25 | 1.125 | 1-14 | 0.5 | 3.18 |

| CF-3-SB | 3 | 1.75 | 4.2812 | 2.5 | 1.25 | 1 1/4 -12 | 0.625 | 4.68 |

| CF-3 1/4 -SB | 3.25 | 1.75 | 4.2812 | 2.5 | 1.25 | 1 1/4 -12 | 0.625 | 5.28 |

| CF-3 1/2 -SB | 3.5 | 2 | 4.7812 | 2.75 | 1.375 | 1 3/8 -12 | 0.75 | 7.06 |

| CF-4-SB | 4 | 2.25 | 5.7812 | 3.5 | 1.5 | 1 1/2 -12 | 0.75 | 10.4 |

| CF-5-SB | 5 | 2.75 | 7.874 | 5.0625 | 2.5625 | 2-1/2 | 0.875 | 19.24 |

| CF-6-SB | 6 | 3.25 | 9.3125 | 6 | 3 | 2 1/2 -12 | 1 | 33.88 |

| CF-7-SB | 7 | 3.75 | 11.4995 | 7.6875 | 4.125 | 3-12 | 1.25 | 55.1 |