▼ Description and Features of SR Track Roller

• The function of series SG rollers are same as the series LFR rollers. But they are mainly used in the flat track and in the condition required compact structure. After rollers are installed to the slider, the shaft will be not or seldom over the roller's side planes. There are two contact points between the roller andtrack, so the contact function is favorable.

• Rollers feature double row angular contact ball bearing in its internal structure design and a thick-walled outer ring so rollers can accommodate higher loads.

• Bearings are made of the high-quality bearing steel, processed by heat treatment and precision grinding, and are filled with a long service life, high-grade and multipurposes grease. Bearings take the metal shields to prevent the dust.

• Can provide the rollers with concentric or eccentric pivot. Some types of the rollers can be made from the corrosion resistant stainless steel.

▼Characteristics of Guide System that series SG track roller are applied

• High allowance speed, low resistance and long life

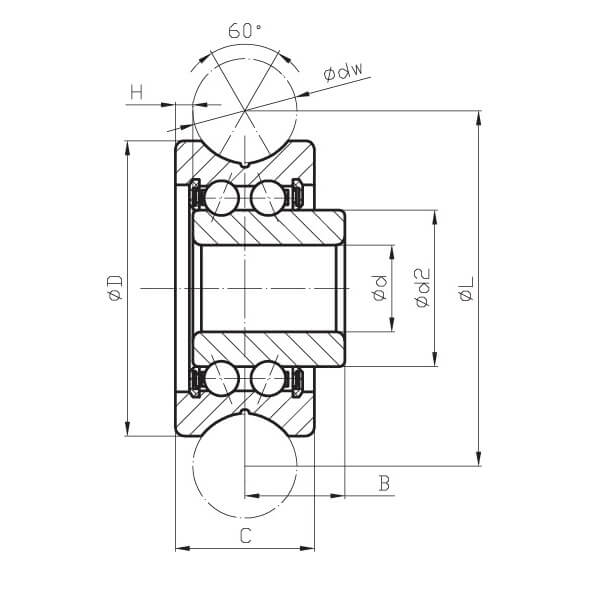

For series SG rollers, the surface profile of the outer ring is designed as the GOTHIC ARCH.When rollers run, there are two contact points with anangle 60 degrees between the roller and track. So the friction resistance is low and the load is in equality thus avoiding the stresses centralization and edge effect caused by the error from installation and manufacturing, making the track system has the characteristics of highspeed, low energy consumption, long service life and minimum noise level.

• Easy installation

After bearing assembled the concentric or eccentric pivot, installation will be convenient. To adjust the eccentric one's eccentricity, the bearing can get the fitting preload.

• Smooth running, minimum error and lower noise level

The high precision machinery and complete inspection facilities make accuracy in the profile of roller. Mature manufacturing techniques and critical inspection procedure make all rollers good in the Kea (radial runout) of outer ring and roundness of working surface, so the guide system in motion is smooth running, minimum error and lower running noise level.

Rings: ultra clean high-carbon chromium steel

Cage: nylon 66

Rolling elements: G10 grade low noise steel ball

Raceway: Fine ground and super finishing

U profile: Fine ground with top class rotary dresser

Closures: NBR / Sheet steel

Tolerance: Up to ISO P5 ( ABEC-5 )Runout: 0.015 -0.02mm, 100% inspection before delivery to customer

Grease: Standard grease Shell Alvania S2

Stainless Steel: on request

| Part No | Dimensions(mm) | Load Ratings(KN) | Liming Speed (r/min) | Weight(g) | ||||||||

| dw | d | D | C | B | L | d2 | H | Cr | Cor | |||

| SG15-2RS | 6 | 5 | 17 | 8 | 5.75 | 20.46 | 8.6 | 1 | 1.78 | 0.94 | 15000 | 8 |

| SG15-10-2RS | 10 | 5 | 17 | 8 | 5.75 | 25.5 | 8.6 | 1 | 1.78 | 0.94 | 15000 | 9 |

| SG20-2RS | 8 | 6 | 24 | 11 | 7.25 | 28.62 | 11.1 | 1.2 | 3.44 | 1.73 | 12000 | 25 |

| SG25-2RS | 10 | 8 | 30 | 14 | 8.5 | 35.77 | 13 | 1.5 | 5.09 | 2.6 | 11000 | 49 |

| SG35-2RS | 12 | 12 | 42 | 19 | 12.5 | 48.93 | 18 | 1.5 | 10.5 | 5.8 | 7000 | 136 |

| SG15N-2RS | 6 | 5 | 17 | 8 | 5.75 | 20.46 | 8.6 | 0.5 | 1.78 | 0.94 | 15000 | 8 |

| SG20N-2RS | 8 | 6 | 24 | 11 | 7.25 | 28.62 | 11.1 | 0.7 | 3.44 | 1.73 | 12000 | 25 |

| SG25N-2RS | 10 | 8 | 30 | 14 | 8.5 | 35.77 | 13 | 1 | 5.09 | 2.6 | 11000 | 49 |

| SG35N-2RS | 12 | 12 | 42 | 19 | 12.5 | 48.93 | 18 | 1 | 10.5 | 5.8 | 7000 | 136 |

| LFR50/5-4N-2Z | 4 | 5 | 16 | 7 | 5 | 18 | 6.9 | 0 | 2.22 | 0.93 | 27000 | 8 |

| LFR50/5-5-2Z | 5 | 5 | 17 | 7 | 5 | 20 | 6.9 | 0 | 2.02 | 0.93 | 27000 | 8 |

| LFR50/5-6N-2Z | 6 | 5 | 17 | 7 | 5 | 21 | 6.9 | 0 | 2.02 | 0.93 | 27000 | 8 |

| LFR50/8-6N-2Z | 6 | 8 | 24 | 11 | 7 | 28 | 12.3 | 0 | 5.09 | 2.6 | 20000 | 25 |

| LFR50/8-8N-2Z | 8 | 8 | 24 | 11 | 7 | 29 | 12.3 | 0 | 5.09 | 2.6 | 20000 | 25 |

• Industrial machinery: printing machinery, paper machinery, automation machinery, textile machinery, vending machines, woodworking machinery, packaging machinery

• Electronic equipment: mechanical arm, measuring equipment, X-X platform, medical equipment, factory automation equipment

• Rotation machinery: metal heat treatment designed nuclear reactor, brakes, etc

• Aerospace industries: aircraft flaps brakes, seat brakes, missiles, airport apparatus and other equipment

• Other: radio antenna brakes, door and window control, medical bed control, parking facilities, machine tool doors, laboratory automation, etc.

• We only accept payment in advance

• The goods must be returned with 30 days and brand new. We will pay the return charges only for the quality problem.

• We do not accept return except quality problem.

The C&H Track Roller is made from high quality material and components with modern facilities. The runout of outer ring and roundness of working surface is controlled very strictly, it is to guarantee smooth running and mini error and low the noise Level.