- Mobile: 0086-18616206301

- Skype:zhou-junliang

- E-mail: jason@chenghuibearing.com

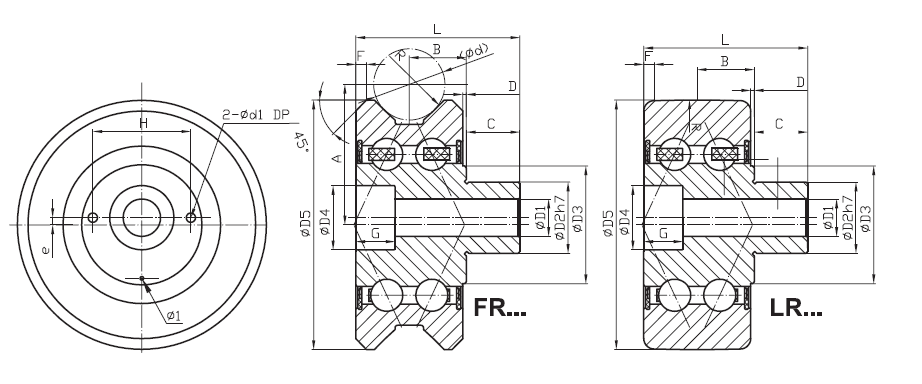

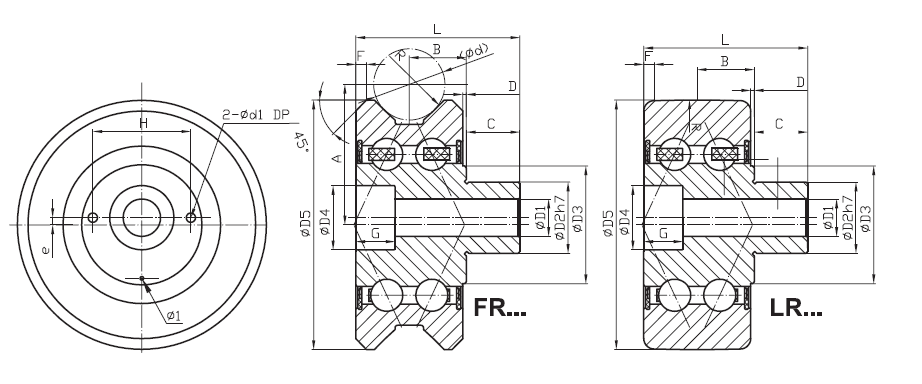

Characteristics of Guide System that series FR and LR Track Roller Bearings

• The backlash setting and the pre-tensioning of the rollers takes place via the eccentric hub of the rollers of the series FR.., FR..R or LR.., LR..R. The FR..Z and LR..Z series are the concentric models. In the eccentric rollers, the inner bolts are provided with two holes. These allow for the adjustment of the backlash. If a roller is located in its zeroposition, the teeth backlash will be the standard value of 0.05 mm flank clearance.The service life of the system will be reduced by excessive tensioning. With too little tension the rollers will not run,or will wear due to the poor meshing.

• The roller guides have a very low coefficient of friction. This value is slightly increased by the fitting of wipers to the rails.

• Elements of the series with the suffix ..R are available i n stainless steel.(X46Cr13, DIN1.4034, AISI420)

Part No |

A | B | C | D | e | F | G | H | L | D1 | D2 | D3 | D4 | D5 | d | d1 | DP | R | Cr | Cor | Mass |

| mm | KN | kg | |||||||||||||||||||

| FR10 | 22.62 | 10.5 | 10 | 1 | 1 | 2 | 6.8 | 15.4 | 30 | 6.4 | 15 | 20.8 | 11 | 42 | 9 | 2.6 | 3 | 200 | 4.9 | 5.3 | 0.15 |

| FR10Z | 22.62 | 10.5 | 10 | 1 | 0 | 2 | 6.8 | 15.4 | 30 | 6.4 | 15 | 20.8 | 11 | 42 | 9 | 2.6 | 3 | 200 | 4.9 | 5.3 | 0.15 |

| FR15 | 29.65 | 12 | 12 | 1 | 1 | 2 | 9 | 18.5 | 35 | 8.4 | 15 | 23.8 | 14 | 53 | 14 | 2.6 | 3 | 250 | 7.2 | 6.8 | 0.25 |

| FR15Z | 29.65 | 12 | 12 | 1 | 0 | 2 | 9 | 18.5 | 35 | 8.4 | 15 | 23.8 | 14 | 53 | 14 | 2.6 | 3 | 250 | 7.2 | 6.8 | 0.25 |

| FR20 | 36.2 | 16 | 15 | 1 | 1 | 3 | 11 | 22.5 | 46 | 10.5 | 20 | 27.7 | 18 | 63 | 20 | 2.6 | 3 | 300 | 10.2 | 9.5 | 0.5 |

| FR20Z | 36.2 | 16 | 15 | 1 | 0 | 3 | 11 | 22.5 | 46 | 10.5 | 20 | 27.7 | 18 | 63 | 20 | 2.6 | 3 | 300 | 10.2 | 9.5 | 0.5 |

| FR22 | 39.4 | 16 | 15 | 1 | 2 | 3 | 11 | 27.5 | 46 | 10.5 | 20 | 33 | 18 | 70 | 20 | 2.6 | 3 | 300 | 24.6 | 16.2 | 0.5 |

| FR22Z | 39.4 | 16 | 15 | 1 | 0 | 3 | 11 | 27.5 | 46 | 10.5 | 20 | 33 | 18 | 70 | 20 | 2.6 | 3 | 300 | 24.6 | 16.2 | 0.5 |

| FR25 | 43.42 | 20.5 | 20 | 1 | 1 | 3.5 | 13 | 27.5 | 60 | 13 | 25 | 35.6 | 20 | 77 | 24 | 4.1 | 4.5 | 360 | 16.3 | 15 | 1.1 |

| FR25Z | 43.42 | 20.5 | 20 | 1 | 0 | 3.5 | 13 | 27.5 | 60 | 13 | 25 | 35.6 | 20 | 77 | 24 | 4.1 | 4.5 | 360 | 16.3 | 15 | 1.1 |

| FR35 | 61.25 | 30 | 25 | 1 | 1 | 7.5 | 17.5 | 42 | 84 | 17 | 40 | 56.9 | 30 | 107 | 35 | 4.1 | 4.5 | 500 | 28.4 | 32 | 2.8 |

| FR35Z | 61.25 | 30 | 25 | 1 | 0 | 7.5 | 17.5 | 42 | 84 | 17 | 40 | 56.9 | 30 | 107 | 35 | 4.1 | 4.5 | 500 | 28.4 | 32 | 2.8 |

| LR10 | 10.5 | 10 | 1 | 1 | 2 | 6.8 | 15.4 | 30 | 6.4 | 15 | 20.8 | 11 | 47 | 2.6 | 3 | 500 | 4.9 | 5.3 | 0.18 | ||

| LR10Z | 10.5 | 10 | 1 | 0 | 2 | 6.8 | 15.4 | 30 | 6.4 | 15 | 20.8 | 11 | 47 | 2.6 | 3 | 500 | 4.9 | 5.3 | 0.18 | ||

| LR15 | 12 | 12 | 1 | 1 | 2 | 9 | 18.5 | 35 | 8.4 | 15 | 23.8 | 14 | 47 | 2.6 | 3 | 500 | 7.2 | 6.8 | 0.45 | ||

| LR15Z | 12 | 12 | 1 | 0 | 2 | 9 | 18.5 | 35 | 8.4 | 15 | 23.8 | 14 | 47 | 2.6 | 3 | 500 | 7.2 | 6.8 | 0.45 | ||

| LR20 | 16 | 15 | 1 | 1 | 3 | 11 | 22.5 | 46 | 10.5 | 20 | 27.7 | 18 | 72 | 2.6 | 3 | 500 | 10.2 | 9.5 | 0.7 | ||

| LR20Z | 16 | 15 | 1 | 0 | 3 | 11 | 22.5 | 46 | 10.5 | 20 | 27.7 | 18 | 72 | 2.6 | 3 | 500 | 10.2 | 9.5 | 0.7 | ||

| LR25 | 20.5 | 20 | 1 | 1 | 3.5 | 13 | 27.5 | 60 | 13 | 25 | 35.6 | 20 | 85 | 4.1 | 4.5 | 500 | 16.3 | 15 | 1.1 | ||

| LR25Z | 20.5 | 20 | 1 | 0 | 3.5 | 13 | 27.5 | 60 | 13 | 25 | 35.6 | 20 | 85 | 4.1 | 4.5 | 500 | 16.3 | 15 | 1.1 | ||

| LR35 | 30 | 25 | 1 | 1 | 7.5 | 17.5 | 42 | 84 | 17 | 40 | 56.9 | 30 | 100 | 4.1 | 4.5 | 500 | 28.4 | 32 | 3 | ||

| LR35Z | 30 | 25 | 1 | 0 | 7.5 | 17.5 | 42 | 84 | 17 | 40 | 56.9 | 30 | 100 | 4.1 | 4.5 | 500 | 28.4 | 32 | 3 |

• Industrial machinery: printing machinery, paper machinery, automation machinery, textile machinery, vending machines, woodworking machinery, packaging machinery

• Electronic equipment: mechanical arm, measuring equipment, X-X platform, medical equipment, factory automation equipment

• Rotation machinery: metal heat treatment designed nuclear reactor, brakes, etc

• Aerospace industries: aircraft flaps brakes, seat brakes, missiles, airport apparatus and other equipment

• Other: radio antenna brakes, door and window control, medical bed control, parking facilities, machine tool doors, laboratory automation, etc.

• We only accept payment in advance

• We only accept return for quality problem. We will pay the return charges only for the quality problem.

• We do not accept return except quality problem.

The C&H Track Roller is made from high quality material and components with modern facilities. The runout of outer ring and roundness of working surface is controlled very strictly, it is to guarantee smooth running and mini error and low the noise Level.